Introduction

Electric steam boilers are a quieter, cleaner, and more eco-friendly solution for generating unlimited volumes of steam than traditional combustion boilers requiring a fuel source. This article provides a complete guide to electric boilers, what they are, how they work, and the benefits you will enjoy when you make the switch.

What is an electric steam boiler?

An electric steam boiler is a type of boiler that uses heat generated by electricity rather than combustible fuel sources to create steam. Like how your hot water jug heats water, an electric boiler passes electricity through a heating element. The element is an electrical resistor that heats as it resists the flow of electricity. The heat generated in the element is used to boil the water stored in the storage tank. A series of pipes from the boiler then carry the hot steam to where you need it.

How do electric steam boilers work?

Electric steam boilers use electricity to generate heat and boil water. Here’s a step-by-step breakdown of the parts involved in turning water into steam so it can work for you:

- Heating Element: The process begins with the element. A heating element is designed to generate heat by resisting the flow of electricity.

- Holding Tank: The holding tank holds the water that will pass through to the boiler. Water is sourced from a central heating system or a dedicated water supply.

- Heat Transfer: As the water is introduced into the boiler, it is directed over or near the heating element, often via pipes or a tank. Water that comes into contact with the heated surface reaches boiling temperatures and is converted it into saturated steam.

- Steam Distribution: Pressure from the expanding gases inside the boiler forces it into pipes where it can be transported to the desired location and used for various purposes, including heating, sterilization, humidification, food processing, and temperature control.

- Control Systems: All electric hot water boilers include control systems that regulate the heating element so the desired steam pressure and temperature can be controlled precisely to ensure its safe and efficient operation.

https://www.youtube.com/watch?v=666RkKcNw_U&t=23s

Are electric steam boilers efficient?

Yes, steam boilers are efficient, making them the preferred option for many industries and applications. Here are a few of the features that make electric steam boilers more efficient than other options:

Energy Conversion: Nearly all the energy used by electric boilers converts into heat energy. This feature significantly reduces energy waste and ensures that most input energy results in usable steam.

On-Demand Operation: An electric steam boiler produces steam much faster than combustible-fueled varieties. The ability to generate steam only when needed significantly reduces standby losses.

Precise Temperature Control: An electric steam boiler offers higher levels of fidelity when it comes to controlling temperatures and

No Heat Loss From Combustion: Flue gases carry significant levels of thermal energy away from the boiler. Using electricity does not produce flue gases, so almost all the thermal energy is transferred directly to the water. The current crop of gas and oil burners operate at 90-94% efficiency, while an electric boiler can do the same work at 99.9% efficiency.

Minimal Maintenance Requirements: There are few moving parts in an electric boiler compared to fuel-heater versions. Fewer moving parts means less maintenance is required to keep the boiler in tip-top condition.

Reduced Standby Losses: A device powered by electricity does not need a pilot light, eliminating standby losses caused by constantly burning fuel.

While the above characteristics help to create a more efficient electric water boiler, there are other factors to consider as well. For example, high-quality electric steam boiler manufacturers will include adequate insulation, accurate control systems, and proper sizing for specific applications. Regular maintenance and monitoring are also essential to ensuring a boiler maintains its efficiency over time.

best $20 deposit bonus in Australia you can check in Au Casinos List. In addition, there’s a chance you’ll win big. If you don’t make a deposit for at least a couple of weeks, you’ll still be able to play games that require higher bets, like progressive slots.

What are the advantages of electric steam boilers?

An electric steam generator provides several advantages over their combustion-driven counterparts, including:

- Efficient Energy Conversion: An electric steam boiler will convert almost all electrical energy into thermal energy. This feature significantly improves efficiency and reduces wastage. In short, you get more steam for every dollar spent on energy consumption.

- Space Savings: Electrical-powered steam boilers are more compact than traditional fossil-fuel units, making them more suitable for installations in buildings and urban environments where space is at a premium.

- Environmentally Responsible: A combustion-powered steam boiler can only use non-renewable fuel sources. However, it’s possible to create electricity from green, renewable energy sources such as solar and wind power, making electric steam boilers the more environmentally responsible option.

- Greater Flexibility: You get more precise control with electricity. Electric boilers can transfer heat faster and more efficiently than other types, meaning you have greater flexibility because you can produce steam whenever required.

- Safety: You do not need to store or use flammable fuels or gases with these types of steam generators, which helps to improve the safety of your home or facilities dramatically.

Electric steam boiler vs gas.

- Gas boilers are more efficient than electric boilers, but they’re also more expensive.

- Gas boilers produce less emissions and require less maintenance than electric steam boilers.

- Electric steam boilers are cleaner and safer than gas boilers because they don’t need combustion or flue gases. They use electricity to heat water and produce steam.

- Electric steam boilers are more reliable than gas-fired ones. This is because they do not have the risk of corrosion from condensation. Traditional boilers that use burning fuel, such as coal, for power generation have this risk.

Application field.

Electric steam boilers are used in the following industries:

- Chemical industry

- Food industry

- Textile industry

- Paper industry

- Heating industry

How do I choose an electric steam boiler?

Selecting the right steam boiler is a big decision, and you must consider various factors to ensure you make the best choice for your use case scenario.

First, determine the steam capacity you will need for your application. Factors such as the size of the space to be heated, the steam demands of your processes, and whether you have any expansion plans should all have some say in your decision.

Get a steam boiler capable of generating the required steam pressure for your application. Different processes and equipment will all have unique needs and pressure requirements, so choose a boiler with enough pressure range.

A steam boiler will incur ongoing costs, but you can mitigate these by choosing a high-efficiency rating. Consider energy conversion efficiency, on-demand operation capabilities, and insulation to reduce energy consumption and operational expenses.

Always check the safety features of your boiler, such as pressure and temperature controls, automatic shut-off mechanisms, and safety valves. Safety should always be a top priority when selecting a steam boiler to help protect your facilities and staff.

What are the maintenance requirements? Boilers requiring less maintenance may cost more initially, but the savings can mount up over time. Check for easy access for inspection, cleaning, and repairs to minimize downtime and ensure optimal performance.

What’s the reputation of the electric steam boiler manufacturer? Do they have a track record of supplying high-quality boilers? You can find a surprising amount of information by reading reviews, checking certifications, and evaluating warranties. Also, check the availability of their technical support and spare parts.

Any boiler you consider must comply with local safety and environmental regulations. If you install one that doesn’t, you could face significant costs for removal and replacement and possible legal issues.

Keeping all the above in mind will help you choose the best boiler for your needs, but remember to ask a qualified boiler specialist or manufacturer for expert guidance and advice.

Maintenance.

- To safely fix the electric steam boiler, turn off the power and release the pressure before starting the maintenance.

- The electric steam boiler needs regular cleaning after a few years of use to prevent rusting of the boiler shell.

- Clean the water level gauge regularly and open the purge valve daily to keep the water level clear.

- The safety valve should be pulled regularly to avoid rust.

- The boiler room equipped with electric steam boilers must ensure natural ventilation to prevent overall corrosion in dark and humid places.

- Please inspect the boiler for water leaks and pipe damage. Additionally, check if there is any water dripping at the valve connection.

- Make sure the electric boiler’s equipment is working properly. Check the electric control cabinet, water treatment, softening water tank, and other parts carefully.

How much does an electric steam boiler cost?

A steam boiler can last for two or three decades when well maintained, but it eventually needs replacement. Whether you are getting a new or replacement steam boiler, how much it will cost will depend on various factors.

The average cost for a steam boiler is around $6,500, but there’s a lot of variation within that average. For example, a home with minimal needs may get away with a boiler that costs just over $3,000, while more significant requirements can raise the price to as high as $10,000 or more.

The best way to get an exact price for a steam boiler is to call your boiler manufacturer and let them know your exact needs. They will then provide a quote for a boiler that can deliver on your requirements.

| Boiler Size (kW) | Cost ($) |

|---|---|

| 100 – 500 | 3,500 – 6,000 |

| 600 – 1,000 | 6,500 – 10,500 |

| 1,100 – 1,500 | 9,500 – 15,000 |

| 1,600 – 2,000 | 13,500 – 20,000 |

| 2,100 – 2,500 | 20,000 – 25,000 |

| 2,600 – 3,000 | 22,000 – 28,500 |

| 3,100 – 3,500 | 26,000 – 30,000 |

| 3,600 – 4,000 | 32,500 – 39,500 |

| 4,100 – 4,500 | 40,000 – 46,000 |

| 4,600 – 5,000 | 42,000 – 50,000 |

Conclusion.

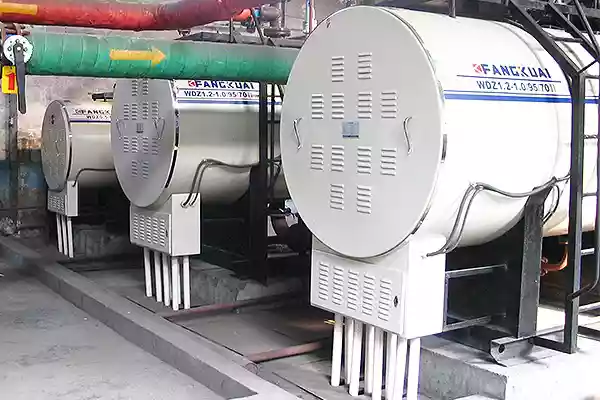

Electric steam boilers are great for home and industry use, as they’re easy to install and maintain. They also provide a lot of benefits over traditional gas or oil boilers in terms of efficiency, convenience, and cost savings. If you need a compact electric steam boiler, this one is worth considering! If you want to know more about electric steam boilers, please contact us at +0086 156-9085-0708.

Get your best price

Quickly compare 3 FREE quotes

- Engineer quick quote

- The overall delivery speed is fast

- Financial choice

- Low installation costs and cost savings

25 years+ of boiler R&D

More than 20 innovative technologies

PRODUCT

-

Gas Boilers

-

Oil Boilers

-

Electric Boilers

-

Coal Boilers

-

Biomass Boilers

-

Industrial Boilers